Pump Manufacturing

Hedunpumps uses ISO-compliant manufacturing processes to improve pump quality, helping our customers improve pump life, reduce pump downtime and minimize your production costs.

#1 Raw Meterial Checking

Our furnace material elements testing adopts the most advanced material inspection equipment—Original Germany spectrometer to ensure the material ratio meeting standard slurry pump requirement.

And we control strictly every process to guarantee that perfect pump and spare parts will be produced.

#2 Casting&Cnc Machining

The casting process involves pouring molten metal into molds and allowing it to cool and solidify.While the machining process is aim to get a perfect shape of pump parts and to remove any defects that may have occurred during the casting process.

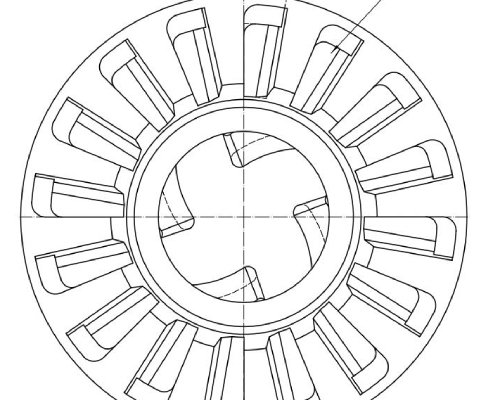

#3 Pump Assembly

After the machining process is complete, the parts of the pump are assembled together. The rotating assembly of the pump is very important, the impeller and shaft are assembled and tested for balance and alignment.

#4 Performance Test

During the manufacturing process of slurry pumps, several tests are performed to ensure that the pump is functioning properly and is able to withstand the harsh conditions of the intended application. These tests include: Hydrostatic testing,Performance testing,NPSH testing,Vibration testing,Noise testing,Dimensional inspection,Material testing,etc.

Pump Hardness Testing

Dynamic Balance Testing

Pressure&Capacity Testing

Professional Slurry Pump Manufacturer in China

Quality Control